Ben-Gurion University Chemists Create Plastic That Sets on Command

Chemists at Ben-Gurion University of the Negev have created a new kind of “smart” plastic that stays liquid until right before it is used, offering a simpler and more flexible way to make, print, or repair materials.

The discovery, reported last month in Nature Chemistry, tackles a long-standing challenge in materials science: how to control exactly when plastics set. Until now, most efforts have focused on designing special catalysts that remain inactive until triggered. Those catalysts can be costly, fragile, and difficult to use outside tightly controlled lab settings.

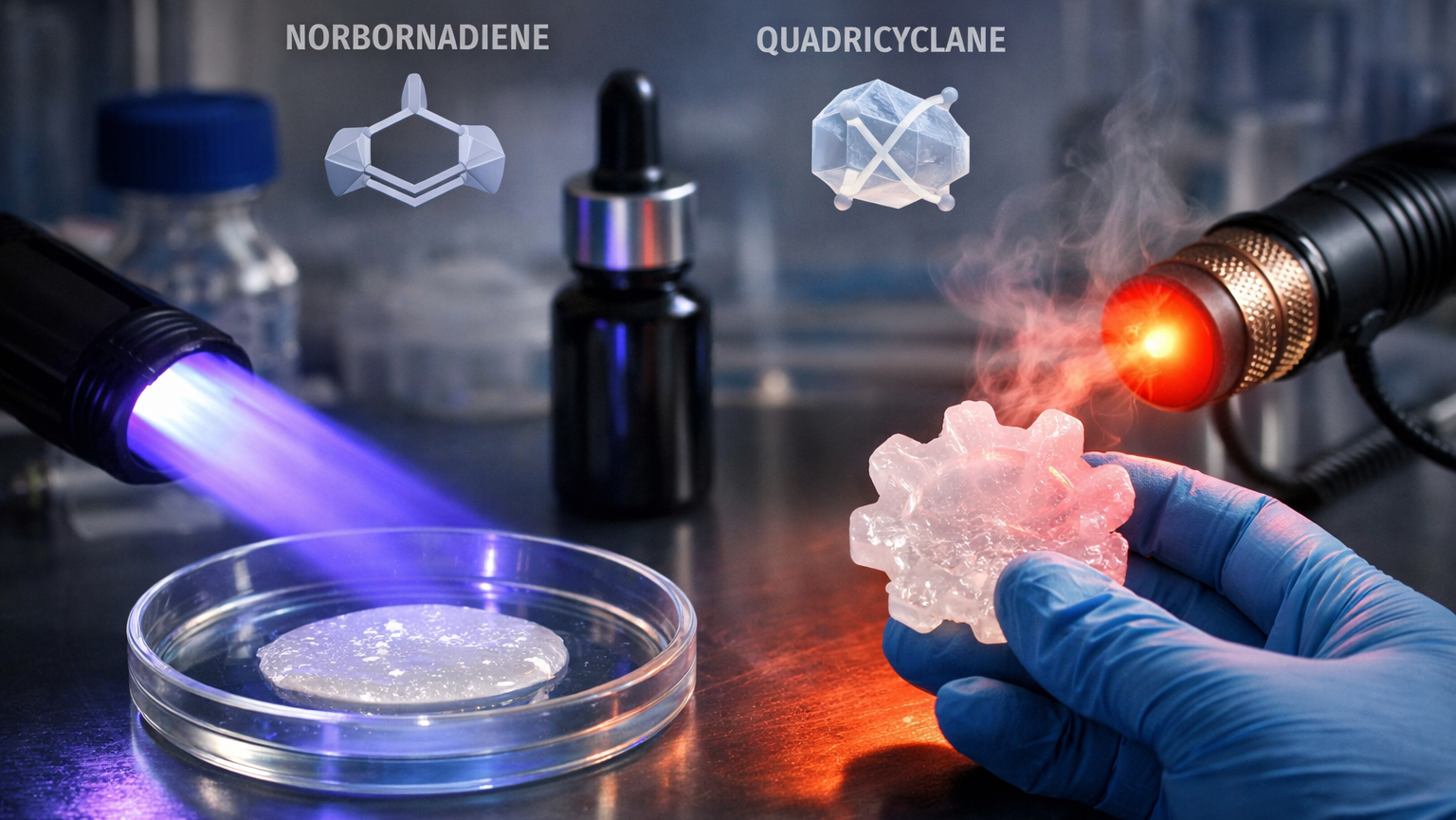

The Ben-Gurion University team took a different route. Rather than placing the on-off switch in the catalyst, they embedded it directly into the building blocks of the material itself. These building blocks, known as “latent monomers,” are stable liquids that can sit unchanged for weeks. When exposed to light or gentle heat, they suddenly link together and form a solid plastic-like material.

Give the gift of hope

We practice what we preach:

accurate, fearless journalism. But we can't do it alone.

- On the ground in Gaza, Syria, Israel, Egypt, Pakistan, and more

- Our program trained more than 100 journalists

- Calling out fake news and reporting real facts

- On the ground in Gaza, Syria, Israel, Egypt, Pakistan, and more

- Our program trained more than 100 journalists

- Calling out fake news and reporting real facts

Join us.

Support The Media Line. Save democracy.

“This work demonstrates a new way of thinking about a general problem in polymer science and will hopefully inspire scientists in the field to look at the challenges in their own work with a fresh point of view,” Nir Lemcoff, a PhD student and one of the study’s lead authors said in a press release.

The system relies on small molecules called norbornadienes, which are commonly used to make plastics. Under ultraviolet light, these molecules flip into an inactive form that cannot link into chains. Later, mild heating switches them back into their active form. To do this efficiently and precisely, the researchers used tiny gold nanoparticles that warm up only in their immediate surroundings when illuminated with near-infrared light.

“Instead of a ‘sleeping’ catalyst, we created ‘sleeping’ building blocks of the material itself,” said Prof. Yossi Weizmann, who led the study. “The mixture can sit quietly on the shelf for weeks and will snap together into a solid only when you shine light on it or warm it up. That kind of on-demand, light-driven curing could make industrial production, printing, and repair processes safer, simpler and more energy-efficient.”

The approach opens practical possibilities. Manufacturers could store ready-to-use liquids without worrying about premature hardening, shape or print parts first, and then cure only selected areas using light. The researchers also showed they can combine different types of building blocks to create materials with multiple properties, or make an object soft at first and strengthen it later in a single process.

The work was supported by the Israel Science Foundation and the United States–Israel Binational Science Foundation.